Heavy gang milling of milling machine tables They remove material by their movement within the machine (e.g., a ball nose mill) or directly from the cutter's shape (e.g., a form tool such as a hobbing cutter). There are cutting tools typically used in milling machines or machining centers to perform milling operations (and occasionally in other machine tools). Thin film coatings may be applied to decrease friction or further increase hardness. More expensive but slower-wearing materials include cemented carbide. A low cost cutter may have surfaces made of high speed steel. The cutting surfaces of a milling cutter are generally made of a hard and temperature-resistant material, so that they wear slowly. Tools optimized for face milling tend to have only small cutters at their end corners. Milling cutters may also have extended cutting surfaces on their sides to allow for peripheral milling. Milling cutters such as end mills may have cutting surfaces across their entire end surface, so that they can be drilled into the work piece (plunging). Many different types of cutting tools are used in the milling process. Peripheral milling is well suited to the cutting of deep slots, threads, and gear teeth. In this case the blades of the cutter can be seen as scooping out material from the work piece.

This led to a new class of machine tools, multitasking machines (MTMs), which are purpose-built to facilitate milling and turning within the same work envelope.įace milling process (cutter rotation axis is vertical - 0° inclination relative to tool axis) The integration of milling into turning environments, and vice versa, began with live tooling for lathes and the occasional use of mills for turning operations. Milling centers are generally classified as vertical machining centers (VMCs) or horizontal machining centers (HMCs). After the advent of computer numerical control (CNC) in the 1960s, milling machines evolved into machining centers: milling machines augmented by automatic tool changers, tool magazines or carousels, CNC capability, coolant systems, and enclosures. The original class of machine tools for milling was the milling machine (often called a mill). Milling can be done with a wide range of machine tools. It is one of the most commonly used processes for machining custom parts to precise tolerances.

Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. This may be done varying direction on one or several axes, cutter head speed, and pressure. Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece.

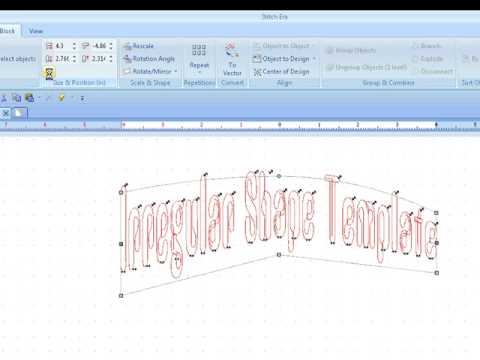

#Stitch era universal tutorial micro font full

Full view of a 3-axis clone of a Bridgeport-style vertical milling machine

0 kommentar(er)

0 kommentar(er)